To meet the increasing demand for greater volumes and lower costs in production with high quality, ABB turned to JOT Automation for a fully automated, custom assembly line solution for the manufacturing of low voltage power switches.

ABB’s Smart Power business unit, located in Finland, is the market leader for low voltage switches globally. Their factory in Vaasa produces a wide range of low voltage switches for solar, auxiliary power, IT, and industrial use.

ABB’s switches are in high demand and they have to be able to meet both demand and expectations. As such, ABB turned to us at JOT Automation for a custom line solution that can:

- increase production volume while maintaining profitability

- handle a considerable amount of requirements

- meet even the most ultimate quality standards.

We have delivered the solution, and now we can break it down for you to read.

What we did to help abb

So, automating ABB’s low voltage switch production had high expectations at ABB’s end, and we of course wanted to rise to the challenge. Essentially, before getting down to automation, we broke down the initial setup into what the application is and what the challenge is. By analyzing these two we were able to provide the best possible solution for ABB.

The Application

Manufacturing of low voltage power switches that require high levels of accuracy in the assembly and testing phase.

The challenge

- Increasing manufacturing volumes while maintaining the highest quality standards in the industry.

- Manufacturing multiple product variants requires an extremely high level of accuracy and flexibility, while speed is key to ensuring maximum profitability.

The solution

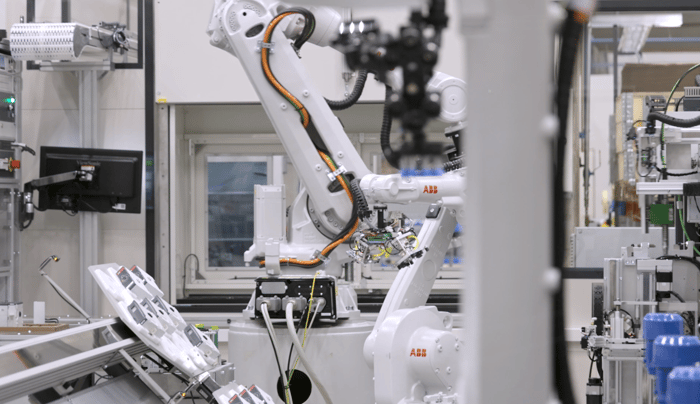

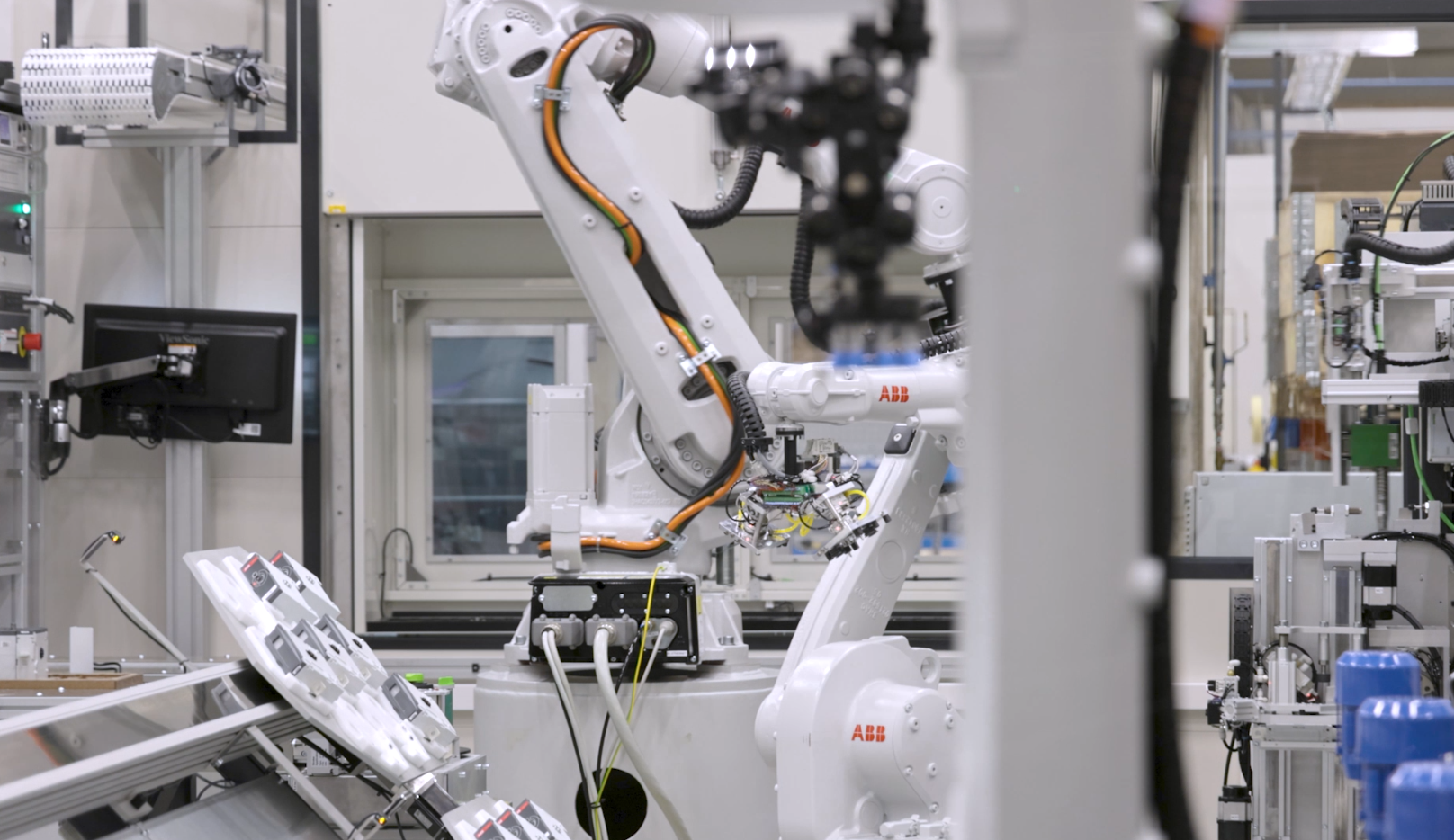

- Fully automated custom assembly line for the manufacturing of low voltage power switches.

- Ability to run 2 product families with up to 40 different product variants, including semi-autonomous production.

- Five-fold increase in throughput.

JOT’s custom automated line handles the assembly and testing of various components, fed from incoming material stations with up to two hours of autonomous production buffer. A sophisticated machine vision-based system for picking and placing of components ensures a reliable and quick sub-30-second cycle time throughout.

Components are picked and placed dynamically based on the orders given by the MES, or manufacturing execution system. The production consists of two entire product families for power switches, with up to 40 different product variants. Talk about diverse production for one single line!

The assembly is handled dynamically on various smaller assembly stations. These include parts and feet assembly, screw insertion, and end product labeling for 100% tracking and traceability throughout the production process.

For testing purposes, the line is equipped with both mechanical and electrical testing capabilities. The test applications’ purpose is to ensure that these heavy-use industrial products are up to the ultimate quality and reliability standards.

After multiple testing phases, the products are finally picked and placed on the outgoing conveyor to transport them to the packaging station and made ready for shipping.

The result – a successful solution for ABB

The complete lineup is now in use at ABB’s Vaasa factory. The implementation of our automation solution has increased their production throughput five-fold. All the while, the quality of production has not been negatively affected, meaning ABB can deliver more of their product without compromising on their quality standards.

“Together with JOT, we generated a solution that allows us to fully automate our production. We required a supplier that can meet demanding requirements while providing industry-leading reliability and quality.” Juha Sohlberg, Senior Project Manager at ABB.

“We are happy with JOT’s quality and technical solution. With this custom line solution, we are able to increase our throughput while maintaining production flexibility”, Juha Sohlberg states.

If you are interested in learning more about our custom automation solutions and capabilities, please be in touch.

About ABB

ABB is a leading global technology company that energizes the transformation of society and industry to achieve a more productive, sustainable future. They operate in four business areas that are made up of 20 divisions, with their Smart Power business unit being the global leader for Low Voltage products and systems. ABB provides a full range of low voltage solutions to connect, protect, control, and measure a wide range of electrical installations, enclosures, switchboards, electronics, and electromechanical devices.

5x production boost for ABB with custom automation solution" width="600" loading="lazy">

5x production boost for ABB with custom automation solution" width="600" loading="lazy">