ANT Plant Microfactory for led manufacturers

Watch the ANT Plant Microfactory in action

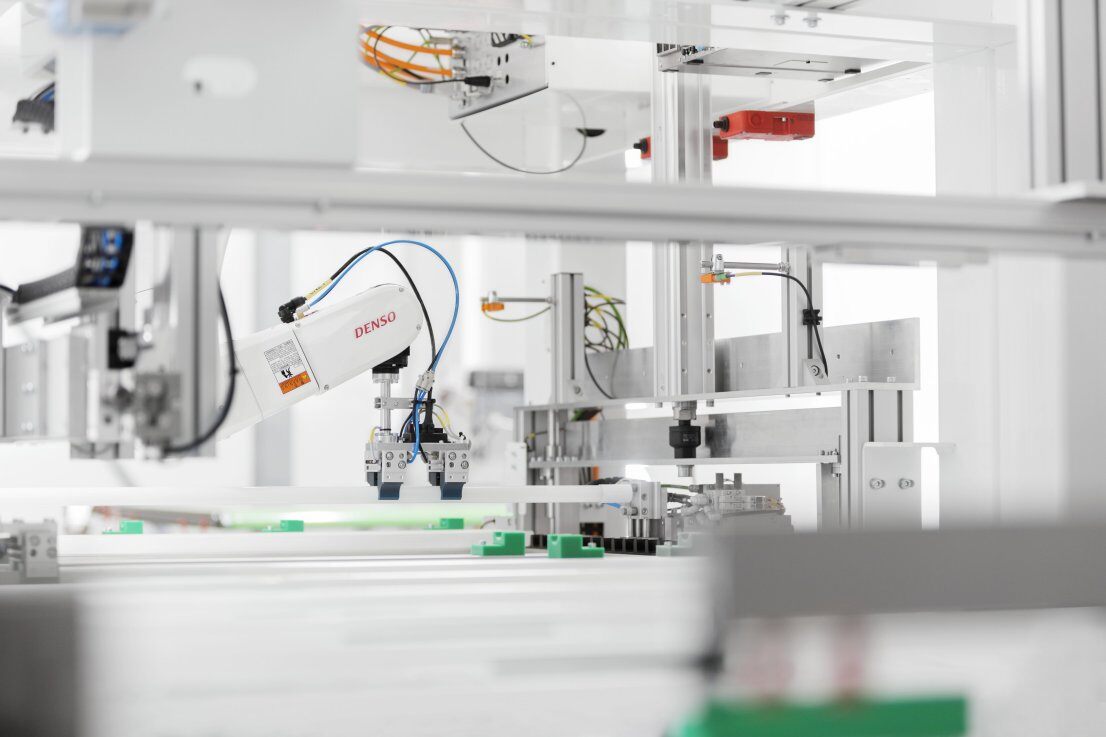

The ANT Plant Microfactory is a quick-to-adopt automation solution with advanced manufacturing robotic cells. The modular structure of the microfactory enables quick changes to the production line, a lower total cost of ownership and quicker ramp-up times.

See how we helped one of our LED manufacturing customers transform their production with the modular ANT Plant Microfactory.

ANT PLANT – THE MODULAR, FULLY AUTOMATED TURNKEY MICROFACTORY

You can choose a combination of fully automated standardized robotic cells that will fit your LED lighting manufacturing needs most effectively. We offer various technology applications for robotic cells, including assembly, testing, laser marking and packaging. The installation of the complete Microfactory at the client’s premises can be done in only eight hours, as the interface between the cells is simply about connecting the power lines and the communications network. Thanks to the streamlined standard platforms, the estimated payback time for your microfactory is significantly less than that of a traditional custom automation project.

The modular structure of the Microfactory enables quick changes to your LED lighting production line. Typically, the ANT Plant Microfactory manufactures products with several value-adding process steps, including assembly and subassembly, testing, housing etc.

.png?width=1600&height=400&name=microfactory%20delivery%20process%20flow%20(1).png)

WHY Choose the ANT PLANT Microfactory CONCEPT?

The ANT Plant Microfactory concept is a modular, automated assembly platform for LED manufacturers that is flexible, scalable and compact. Each module typically contains one application, and they are integrated through standard, pre-tested, and verified interfaces end-to-end. This enables LED manufacturers to customize and implement the line configuration and capacity flexibly according to their needs – yet the microfactory delivery time can be up to 30% quicker than a traditional automation system. And, the onsite installation time can be even up to 90% faster – in fact, a microfactory can be installed in one day.

Throughout the entire life cycle, modularity enables you to flexibly adapt to production changes, run higher product-mix, and scale capacity. With full automation and robots, you can lower operational costs while increasing quality and yield radically. Automation requires less space and operational staff, which reduces the lifetime costs dramatically. The ANT Plant Microfactory provides more flexibility, faster customer response times, and higher quality while reducing costs in the long run.

With our ANT Plant concept, we are bringing affordable manufacturing automation to everyone.

Profitable

- Low total cost of ownership

- Increase in the value of the company brand

- Competitively priced high-quality products

- Smart platform design

Flexible

- Short lead times

- Fast response time to ever-changing client demands

- Small batch production runs

- Unparalleled footprints

Easy operation

- Focus on expanding your core business

- Innovative visions for product development with JOT Automation

- Improving risk management

Modular design

- Modular on platform and application level

- As quick as a one-day installation

- A two-week ramp-up to full capacity

- Additional cells can be added later, and the setup time can be as short as two hours

Fully automated

- Products are tested, labeled, and packaged automatically

- Only one person per shift needed to keep the production running 24/7

- Operations can be monitored from the cloud

Quality Control

- Design for Automation (DFA): process and the end product are designed at the same time, which means no compromises with the process or product design

- No human errors with automated process phases

WHAT IS THE ANT PLANT MANUFACTURING CONCEPT?

Our manufacturing concept is a comprehensive turnkey solution enabled by a fully automated microfactory, and a supportive partnership with JOT Automation. Thanks to ANT Plant, LED manufacturing is made profitable and easy at your local facility – close to your clients. Features include:

- An easy-to-use interface

- A stable operating system

- Communications network with secured external connection point for remote control and data collection

- One single person per shift needed to keep production running 24/7

Typical applications:

-

Assembly and subassembly

-

Conveyors and conveyor tracking

-

Dispensing of glues and similar masses

-

Flexible feeders

-

Heat staking

-

Hot bar soldering

-

Labeling & laser marking

-

Laser marking equipment

-

Machine vision applications

-

Manipulators

-

Material handling

-

Packaging

-

Screwing

-

Sticker feeders

-

Testing

-

Ultrasound welding

Download e-Guide: ANT Plant Microfactory

The ANT Plant Microfactory concept in a nutshell

The ANT Plant Microfactory concept is an easy solution for manufacturing various products locally. Successful customer cases have demonstrated that local manufacturing costs can be reduced to a more competitive level compared to importing.

The ANT Plant Microfactory makes LED manufacturing more flexible, with faster lead times and rapid product runs. Superior product quality is the primary advantage of microfactories. With fully automated production and automated testing, manufacturers can substantially increase the quality of products by eliminating human errors and delivering 100% tested products.

As the product price competition intensifies, the pressure to lower manufacturing costs increases. The ANT Plant Microfactory provides more flexibility, faster customer response times, and higher quality while reducing costs in the long run. Who wouldn't want that?