Low costs and fast ramp-up time are critical when building a new assembly line or scaling up existing capacity. However, often, time and money are wasted dimensioning the equipment to match your capacity needs and testing incompatible interfaces – lack of modularity slows down time–to–production and break–even.

With a fully modular platform, you can customize the automated assembly line precisely according to your needs. A modular platform can be installed quickly, even in one day. And, when you need to scale capacity, simply add more modules!

This blog introduces a fully modular microfactory platform that enables you to build an automated assembly line quickly and with minimum initial investment!

Download Guide – How to build scalable production with a modular microfactory platform?

Full Modularity

Full modularity is achieved at two levels. The automated assembly line consists of one or more modules, which are combined through standardized interfaces. Each module hosts a production application. The applications are also modular and equipped with standard interfaces to enable smooth integration across the assembly line.

Modules

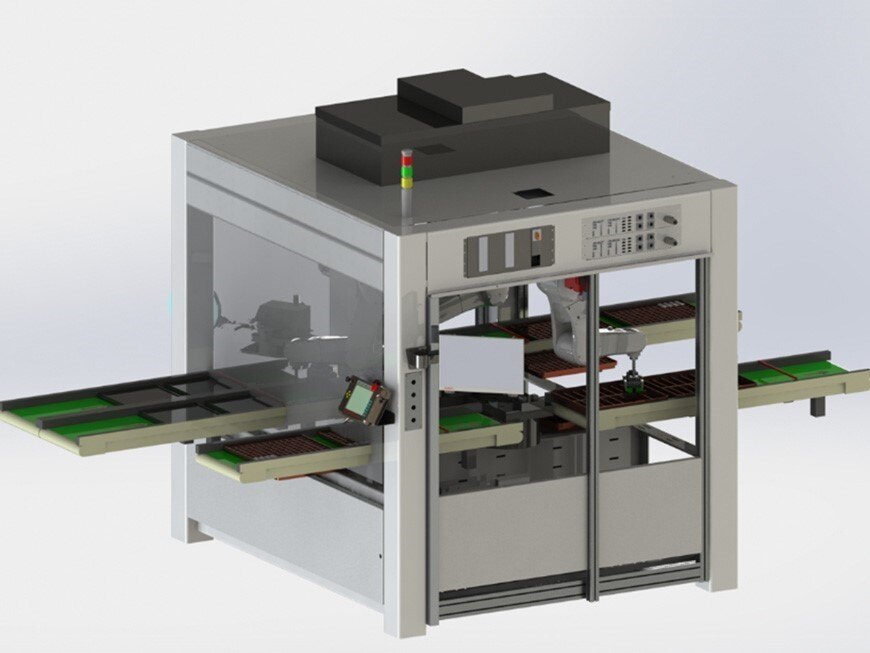

An automated assembly line is built from standardized modules. Each module can have several functions, or applications, which are also modular. Thanks to the modular structure and standardized interfaces, you can combine and integrate the modules to create a fully automated line customized for your needs. Modularity allows you to build an assembly line quickly, add more capacity when needed, and reconfigure the line flexibly. JOT Automation provides compact, fully standardized modules with a minimum floor space requirement.

Applications

Each module can be equipped with various production applications, such as robotic arms, machine vision devices, laser marking equipment, manipulators, sticker feeders, heat staking, hot bar soldering, ultrasonic welding, screwing, dispensing of glues and similar masses, flexible feeders, conveyors, and conveyor tracking appliances. More applications are developed continuously to fulfill your needs.

Benefits of a Fully Modular Assembly Line

Why is modularity critical in today’s manufacturing? Because of competition! You need to ramp up production fast to speed up time to market and minimize investment to improve break-even and ROI. Modularity offers all that.

A fully modular assembly line is easier to design, and standardized interfaces reduce compatibility issues and accelerate the deployment process.

Modularity also enables better scalability. You can minimize the initial investment with a small assembly line. When the demand grows, add more modules to increase capacity.

Throughout the entire life cycle, modularity enables you to flexibly adapt to production changes, run higher product mixes, and scale capacity. With full automation and robots, you can lower operational costs while increasing quality and yield radically. Automation requires less space and operational staff, which reduces the lifetime costs dramatically.

A fully modular assembly line is more than just a manufacturing solution—it's a strategic asset that drives competitiveness and growth. By embracing modularity, you gain:

- Faster time-to-market

- Optimized investment and improved ROI

- Scalability to match your growth

- Flexibility to adapt to market changes

- Cost-effective automation

- Future-proof manufacturing capabilities

In an era where agility and efficiency are paramount, a modular assembly line provides the foundation for manufacturing success. It allows you to start small, dream big, and adapt quickly — positioning your business to thrive in today's dynamic manufacturing landscape.

Examples of Modular Automated Assembly Lines

JOT Automation has delivered several fully modular automated assembly and production lines based on the ANT Plant microfactory solution. Here are two examples.

Case: Automated Sensor Production – One Module

One of the leading global providers of highly advanced sensing technology implemented a fully automated, modular microfactory platform for producing new types of NDIR sensors. Only one module was needed to run the assembly process, quality verification, and packing. Only one operator per shift is required to ensure that production runs smoothly while minimizing operational costs. Eventually, the microfactory increased product quality and opened new customer segments for the customer!

Outcomes:

- Increased product quality

- Expanded customer segments

- Minimized operational costs

Case: Automated LED Assembly – 6 Modules

A Finnish manufacturer of high-quality LED lighting solutions built a modular automated production line based on JOT Automation’s microfactory platform. Its industry-scale production needed only six modules occupying just 60 m2 of floor space. The modules included loading, assembly, aging, testing, laser marking, and packaging.

Outcomes:

- Efficient industry-scale production

- Optimized use of factory space

- Streamlined end-to-end manufacturing process

Take the Next Step in Manufacturing Innovation

Ready to revolutionize your production process? Our fully modular microfactory platform offers:

- Rapid deployment

- Minimal initial investment

- Unparalleled flexibility

- Scalability for future growth

Don't let outdated manufacturing processes hold you back. Contact JOT Automation today to discover how our innovative technology and field-proven expertise can transform your production line. Contact us today!